The ideal syringe for administering intravitreal injections does not exist. With improved awareness of the drawbacks of existing devices and the characteristics desired for intravitreal use, however, syringe manufacturers are stepping up to design products that will help maximize the safety and efficiency of intravitreal injection, said Gustavo B. Melo, MD, PhD.

“Retina specialists are well aware that intravitreal injection can lead to the presence of silicone droplets in the vitreous. The droplets come from the syringes used for injection because most are manufactured with silicone oil to allow for better glide of the plunger. In addition, almost all needles are dipped in a silicone oil bath to coat the outer surface to enable tissue penetration,” said Melo, associate researcher at the Federal University of São Paulo and head of the ophthalmology residency at Sergipe Eye Hospital, Brazil.

“Available data show these droplets matter,” Melo added. “In the 2018 American Society of Retina Specialists PAT survey, 5% of US retina specialists said they had done vitrectomy for symptomatic droplets and 2% have patients seeking legal action of their floaters. In addition, silicone droplets are linked to inflammatory reactions after aflibercept injection.”

Defining the ‘ideal’ syringe

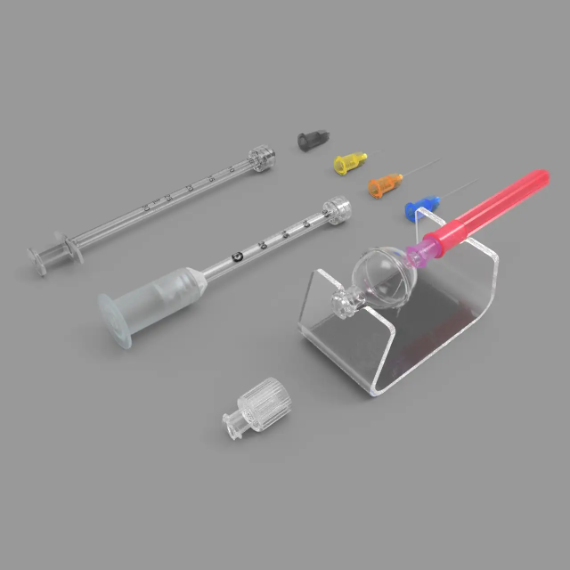

According to Melo, the ideal syringe for intravitreal injections would be silicone oil-free, have negligible dead space to minimize waste of expensive medication, use an attachable needle, giving physicians the option to choose their needle, and feature a Luer-lock tip that allows for an attachable needle and prevents liquid leakage along with accidental needle removal.

“Preferably, it would also be designed for ophthalmic use,” Melo said.

Outlining product pros and cons

Melo and Geoffrey G. Emerson, MD, PhD, private practice, Retina Center of Minnesota, undertook a review of the advantages and disadvantages of syringes used for intravitreal injections, including those that are among the most commonly used in the Americas and Europe along with emerging products. Information on silicone oil released by each syringe was based on scientific publications and personal research. Clinical and scientific experiences were the foundation for comments on additional features.

“Our review included the syringes that we are aware of are being used for intravitreal injection. Other syringes, both good and bad, may be available,” Melo said.

The Ocuject syringe (SJJ Solutions), which is expected to receive CE and FDA certification in mid-2021, seems to meet all of the ideal criteria outlined by Melo. It is silicone oil-free, has a low volume of dead space, a Luer-lock tip, and is designed for ophthalmic use.

The StaClear syringe (Tribofilm Research) was recently cleared for marketing by the US FDA for use in intravitreal injections. It has low dead space and low particulates, complying with USP Chapter 789 testing for ophthalmic solutions. The StaClear syringe is manufactured with a silicone lubricant, but the lubricant is fixed to the lumen of the syringe.

The Zero Residual Luer Lock syringe (SJJ Solutions) is another syringe that has a lot of positive characteristics. It has a low volume of dead space, a Luer-lock tip, can be prefilled air-free, and is designed for ophthalmic use. While it is not silicone oil-free, it is lubricated with a small amount of silicone oil.

Similarly, the Crystal Zenith syringe (West Pharmaceutical) and Plajex (Terumo) have the advantages of being silicone oil-free and having a Luer-lock tip. In addition, the Crystal Zenith complies with USP 789. However, both syringes have significant dead space and are not available to be filled at point of care.

The Injekt-F (B. Braun) and NormJect (HSW) offer the important advantage of being silicone-free. However, they both have moderate dead space and a Luer-slip tip.

“The protruding tip of the Injekt-F syringe helps to minimize dead space. However, the design of this syringe can lead to some confusion regarding the injected volume,” Melo said.

The longer list

The BD Luer-Lok syringe (Becton Dickinson Co), which is distributed with aflibercept in some markets, has a Luer-lock tip. On the downside, however, it is siliconized, albeit being manufactured with a small amount of silicone oil. In addition, this syringe has a large dead space that wastes expensive drug, and it is heavy.

Similarly, the BD Plastipak syringe (BD), which is available worldwide, and the BD Tuberculin syringe (BD), which is more commonly used in the US, are siliconized and have significant dead space. As another disadvantage they have a Luer-slip tip.

Available in many markets, the BD Ultra-Fine syringe (BD) is an insulin syringe with the advantage of having negligible dead space. However, it is siliconized with a large amount of oil.

“This syringe is notorious for its association with silicone oil droplets in the vitreous, and it has a fixed needle that cannot be substituted,” Melo said.

Distributed with ranibizumab (Lucentis, Genentech) in some markets, the Omnifix-F syringe (B. Braun) is siliconized but with just a small amount of silicone oil. However, it has significant dead space and a Luer-slip tip.

The Comfort Point syringe (Exel) is available in the US. It has negligible dead space but a fixed needle, and while it is also siliconized, it releases less silicone oil than the BD Ultra-Fine syringe, Melo said.

Available in many markets, the insulin syringe manufactured by Terumo Medical also has a low volume of dead space. However, it has a fixed needle and releases a large amount of silicone oil.

Gustavo B. Melo, MD, PhD

This article is based on a video presentation from Melo at the EURETINA 2020 virtual meeting. Melo and Emerson have no financial interests to declare.